what is a circular connector

Circular connectors are an essential component in the world of electrical and electronic connections. They serve a wide range of applications and are found in various industries, including aerospace, automotive, and industrial manufacturing. These connectors are known for their durability, reliability, and ability to withstand harsh environmental conditions. In this article, we will explore what circular connectors are, how they work, and their different types and applications.

What is a Circular Connector?

A circular connector, also known as a round connector, is a type of electrical connector that utilizes a circular interface to connect two or more devices. These connectors come in various sizes, shapes, and configurations to accommodate different types of connections. They are designed to provide a secure and reliable connection for signals, power, or data transmission. The circular shape of these connectors allows for easy and quick mating, making them ideal for applications where frequent connections and disconnections are necessary. Circular connectors are commonly used in harsh environments where resistance to moisture, dust, vibration, and corrosion is essential.

Circular connectors are available in different styles, including threaded, bayonet, push-pull, and snap-lock designs. Each style offers unique features and benefits, making them suitable for specific applications. These connectors can be found in a wide range of devices and equipment, such as medical devices, military and aerospace systems, telecommunications equipment, and industrial machinery.

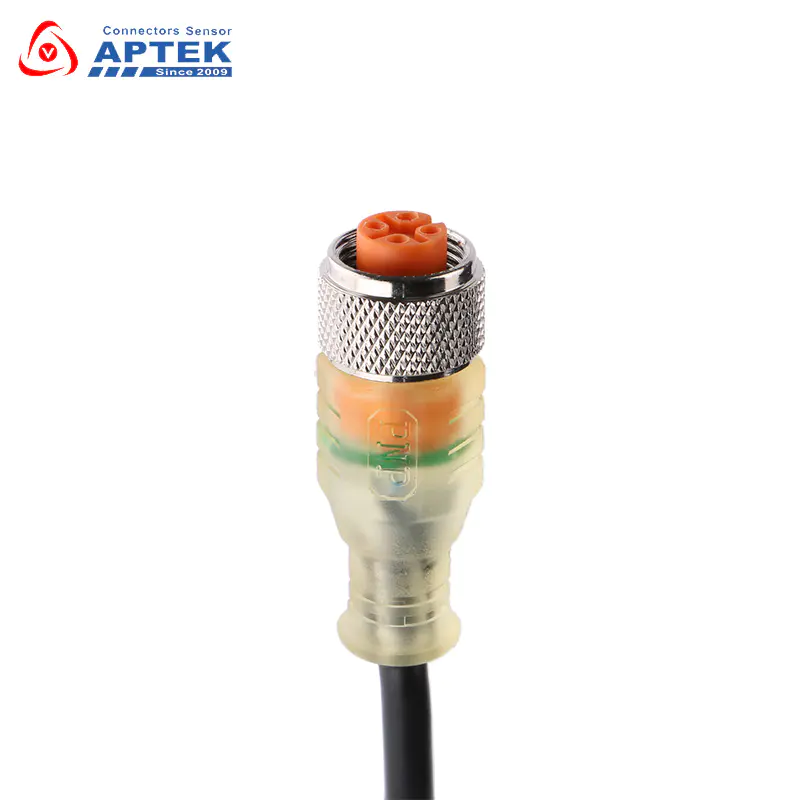

The Anatomy of a Circular Connector

Circular connectors are comprised of several key components that work together to provide a secure and reliable connection. These components include the connector body, contacts, locking mechanism, sealing features, and backshell. The connector body, often made of metal or plastic, houses the internal components and provides the interface for mating. The contacts, which are made of conductive material such as copper or gold, are responsible for carrying electrical signals or power between the connected devices.

The locking mechanism is designed to secure the connection and prevent unintended disconnection due to vibration or movement. This can be achieved through threaded couplings, bayonet locks, or other types of latching mechanisms. Sealing features, such as O-rings and gaskets, are used to protect the connector from moisture, dust, and other environmental contaminants. Backshells, or cable glands, are used to secure and protect the cable as it enters the connector, providing strain relief and additional environmental sealing.

Understanding the Different Types of Circular Connectors

Circular connectors are available in a wide range of configurations to meet the specific requirements of different applications. Some of the most common types of circular connectors include:

- Threaded Circular Connectors: These connectors feature a threaded coupling mechanism that provides a secure and reliable connection. They are commonly used in industrial and commercial applications where high vibration and shock resistance are necessary.

- Bayonet Circular Connectors: Bayonet connectors utilize a quick-connect bayonet coupling mechanism that allows for easy and rapid mating and unmating. They are often found in military, aerospace, and medical applications.

- Push-Pull Circular Connectors: Push-pull connectors feature a self-latching mechanism that allows for quick and easy mating and unmating. They are frequently used in medical devices, audiovisual equipment, and industrial sensors.

- Snap-Lock Circular Connectors: Snap-lock connectors utilize a snap-locking mechanism that provides a secure connection while allowing for easy and tool-less mating and unmating. They are commonly used in consumer electronics, automotive, and telecommunications equipment.

Each type of circular connector offers unique advantages and may be better suited for specific applications based on factors such as durability, ease of use, and environmental resistance.

Applications of Circular Connectors

Circular connectors are used in a wide range of industries and applications due to their versatility, reliability, and durability. Some of the common applications of circular connectors include:

- Aerospace and Defense: Circular connectors are widely used in military and aerospace applications, including avionics, radar systems, communication equipment, and ground vehicles. The ruggedness and reliability of these connectors make them well-suited for harsh environmental conditions and high-performance requirements.

- Industrial Automation: In industrial automation and control systems, circular connectors are used to facilitate the connection of sensors, actuators, and other devices. Their ability to withstand harsh environmental conditions, such as temperature fluctuations and exposure to chemicals, makes them an ideal choice for industrial applications.

- Medical Devices: Circular connectors play a crucial role in medical devices and equipment, providing a reliable connection for patient monitoring, diagnostic equipment, and surgical instruments. Their compact size, ease of use, and robust construction make them suitable for medical applications where reliability and safety are paramount.

- Transportation: Circular connectors are used in various transportation applications, including automotive, rail, and marine systems. They are employed in vehicle electronics, lighting systems, and communication devices, where they provide a reliable and secure connection for data and power transmission.

- Telecommunications: In the telecommunications industry, circular connectors are used in networking equipment, fiber optic systems, and mobile communication devices. Their ability to withstand environmental challenges, such as moisture and temperature extremes, makes them well-suited for outdoor and remote deployments.

Advantages of Circular Connectors

Circular connectors offer several advantages that make them a preferred choice for many applications. Some of the key advantages of circular connectors include:

- Durability: Circular connectors are designed to withstand harsh environmental conditions, including moisture, dust, vibration, and temperature extremes. This makes them suitable for use in demanding applications where reliability is essential.

- Secure Connection: The locking mechanisms used in circular connectors provide a secure and stable connection, preventing accidental disconnection due to vibration or movement. This ensures continuity of electrical signals and power transmission.

- Quick Mating and Unmating: The design of circular connectors allows for quick and easy mating and unmating, reducing installation and maintenance time. This is particularly important in applications where frequent connections and disconnections are necessary.

- Versatility: Circular connectors come in a variety of sizes, configurations, and styles to accommodate different connection requirements. This versatility makes them suitable for a wide range of applications across various industries.

- Environmental Resistance: Circular connectors are equipped with sealing features that protect them from moisture, dust, and other environmental contaminants. This allows them to be used in outdoor, industrial, and other challenging environments.

Overall, the unique features and benefits of circular connectors make them an essential component in the world of electrical and electronic connections.

In conclusion, circular connectors are a fundamental element in the realm of electrical and electronic connections. They are designed to provide a secure and reliable connection for signals, power, or data transmission across various industries and applications. The different types of circular connectors, such as threaded, bayonet, push-pull, and snap-lock designs, offer unique features and benefits to meet specific requirements. Their durability, reliability, and environmental resistance make them an ideal choice for applications where harsh environmental conditions and high performance are essential. Whether in aerospace, automotive, industrial, medical, or telecommunications applications, circular connectors play a crucial role in enabling seamless and efficient connectivity.