M12 sensor/actuator connectors with M12 locking thread for industrial automation, process control and commercial electronics, it is the most commonly used connector in the factory automation. M12 connectors offer various cable connectors, panel mounting receptacles and installable accessories.

| Connector Serries | M12 |

| Gender | Male |

| Locking type | Fix screw |

| Mounting type | Straight angled |

| Standard | IEC 61076-2-101 |

| Ambient temperature | -20℃ ~ +80℃ |

| Connector overmold | TPE/ TPU |

| Connector insert | PA |

| Connector contacts | Brass with gold plated |

| Coupling nut/screw | Brass with nickel plated |

| Insulation resistance | ≥100 MΩ |

| Contact resistance | ≤ 5 mΩ |

| EMI Shielding | Non-Shielded |

| IP rating | IP 67 in locked condition |

| Locking Design | Anti-Vibration |

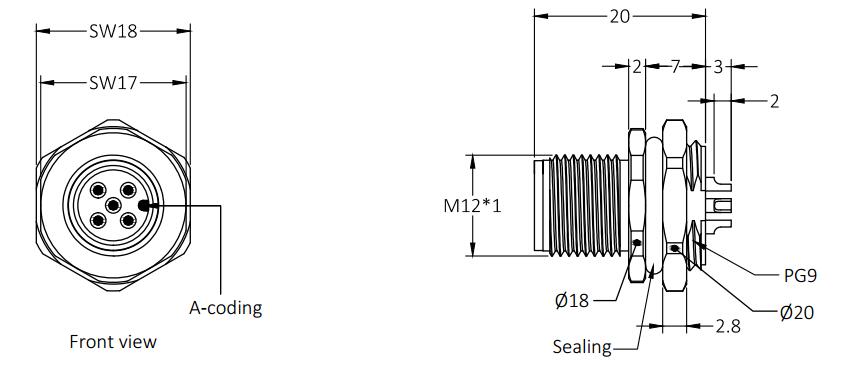

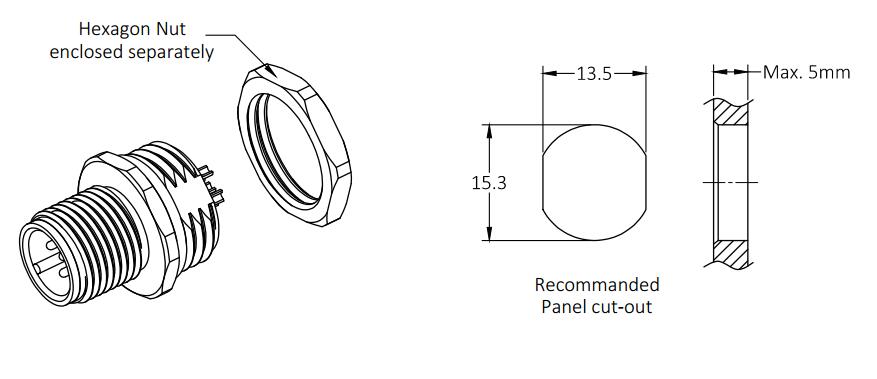

| Mounting Thread | M12, PG9 or M16 |

| Contacts | Available Coding | Wire Termination | Rated current | Voltage | Wire gauge/size | Cable jacket | Wire insulation | Wiring list | Cable ending & length | ||||

| A | B | D | A/C | D/C | AWG | mm² | |||||||

| 03 pins |

|

|

| Solder Version | 4A | 250V | 250V | 24AWG | 0.34 | PUR / PVC | PVC | 1.BN brown 3.BU blue 4.BK black | Customized cable ending and length |

| 04 pins |

|

|

| Solder Version | 4A | 250V | 250V | 24AWG | 0.34 | PUR / PVC | PVC | 1.BN brown 2.WH white 3.BU blue 4.BK black | |

| 05 pins |

|

|

| Solder Version | 4A | 60V | 60V | 24AWG | 0.35 | PUR / PVC | PVC | 1.BN brown 2.WH white 3.BU blue 4.BK black 5.GY grey | |

| 08 pins |

|

|

| Solder Version | 2A | 30V | 30V | 26AWG | 0.25 | PUR / PVC | PVC | 1.BN brown 2.WH white 3.BU blue 4.BK black 5.GY grey 6.PK pink 7.BU blue 8.RD red | |

| 12 pins |

|

|

| Solder Version | 1.5A | 30V | 30V | 26AWG | 0.14 | PUR / PVC | PVC | 1.BN brown 2.WH white 3.BU blue 4.BK black 5.GY grey 6.PK pink 7.BU blue 8.RD red 9.VT violet 10.NV navy 11.OR orange 12.BK black | |

| 17 pins |

|

|

| Solder Version | 1.5A | 30V | 30V | 26AWG | 0.14 | PUR / PVC | PVC | 1.BN brown 2.WH white 3.BU blue 4.BK black 5.GY grey 6.PK pink 7.BU blue 8.RD red 9.VT violet 10.NV navy 11.OR orange 12.BK black 13.WH/GN white/green 14.WH/YE white/yellow 15.WH/GY white/grey 16.WH/RD white/red 17.OR orange | |

Copyright © 2025 Zhongshan Aptek Electronics Technology Co.,Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.