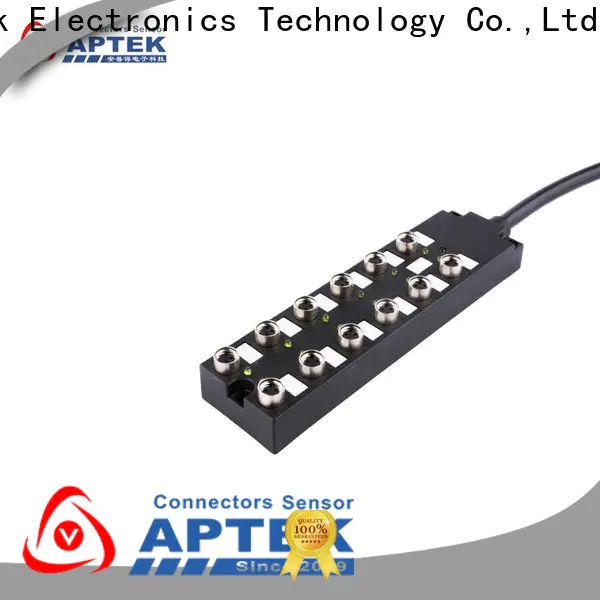

Junction Box provides more extension possiblity to industrial field control. The distribution boxes are available in 4, 6, 8 or 12 ports with either 4 or 5 poles per port. Ther master cable can be configured iva a M23 connector or pre-molded cable on the junction box.

| Connector Serries | Junction Box |

| Ports | 12 |

| Locking type | Fix screw |

| Mounting type | Straight |

| LED Colour | Yellow |

| Ambient temperature | -40℃ ~ +80℃ Fix Installation |

| Material of body | PBT |

| Connector insert | TPU |

| Connector contacts | Brass with gold plated |

| Coupling nut/screw | Brass with nickel plated |

| Body Colour | Black or Yellow |

| Contact resistance | ≤ 5 mΩ |

| Rated Voltage with/without LED | 10~30V/120V |

| Rated current | 2A per signal, 6A total |

IP rating | IP 67 in locked condition |

| Locking Design | Anti-Vibration |

| Seal / O - ring: | FKM |

| Contacts | Coding | Rated current | Voltage | Wire gauge/size | Cable jacket | Cable ending & length | |||

| A/C | D/C | AWG | mm² | ||||||

| 03 pins |

| A-Coding | 2A;6A | 120V | 120V | 22~24 | 0.5~0.25 | PUR / PVC | Customized cable ending and length |

Copyright © 2025 Zhongshan Aptek Electronics Technology Co.,Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.