How about production process for profibus connector?

2020-11-07

There are a few steps in the production of profibus connector. Each measure is of great significance and is taken seriously. Raw materials are significant in the production. They ought to be tested before being processed. During the production, the manufacturing line should be controlled to be sure the output is stable and the quality is fantastic. Quality management is taken. Generally, each production step should be separated by the manufacturer by establishing distinct assignments.

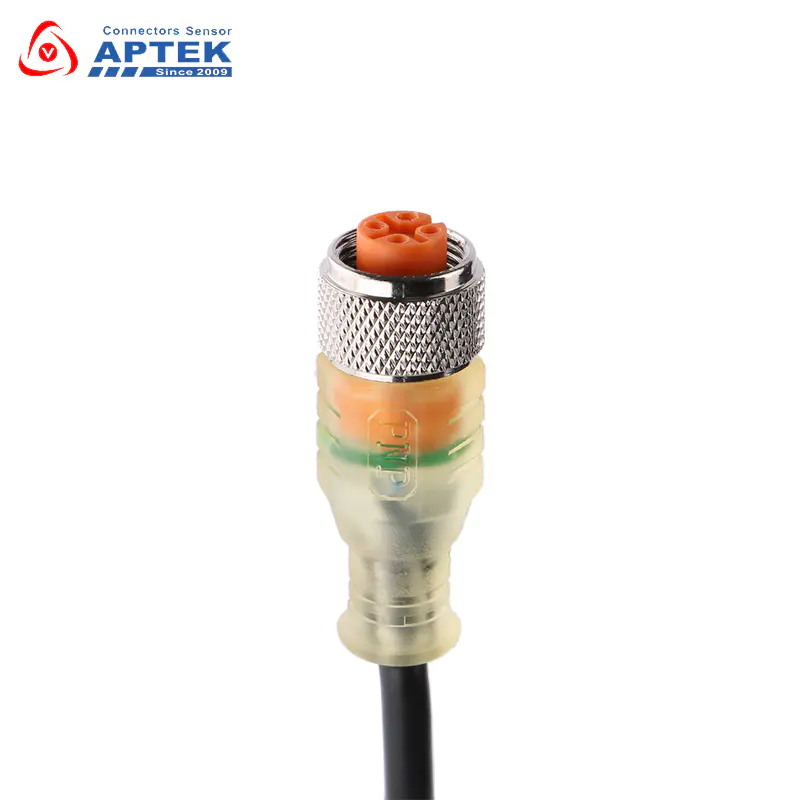

Zhongshan Aptek Electronics Technology Co.,Ltd has an unrivalled competitive edge in designing and manufacturing m12 connector cable. We have been widely recognized in the industry. The circular connectors series is one of the main products of Aptek. Comprehensive quality and performance inspection are carried out on APTEK industrial i/o connectors. They involve scrutinization of size (thickness, width, length, etc.), appearance defects, moisture absorption, and bacterial resistance. APTEK has guaranteed the applications of connectors in food & beverage, chemicals, wood, LED lighting, etc. The product generates no noise during operation. People find it works very quietly without any humming or buzzing which disrupt people's attraction. Founded in 2009, APTEK is a professional manufacturer of industrial waterproof connectors.

We are a high quality professional manufacturer of devicenet connectors. Inquire!

Zhongshan Aptek Electronics Technology Co.,Ltd has an unrivalled competitive edge in designing and manufacturing m12 connector cable. We have been widely recognized in the industry. The circular connectors series is one of the main products of Aptek. Comprehensive quality and performance inspection are carried out on APTEK industrial i/o connectors. They involve scrutinization of size (thickness, width, length, etc.), appearance defects, moisture absorption, and bacterial resistance. APTEK has guaranteed the applications of connectors in food & beverage, chemicals, wood, LED lighting, etc. The product generates no noise during operation. People find it works very quietly without any humming or buzzing which disrupt people's attraction. Founded in 2009, APTEK is a professional manufacturer of industrial waterproof connectors.

We are a high quality professional manufacturer of devicenet connectors. Inquire!

Custom message